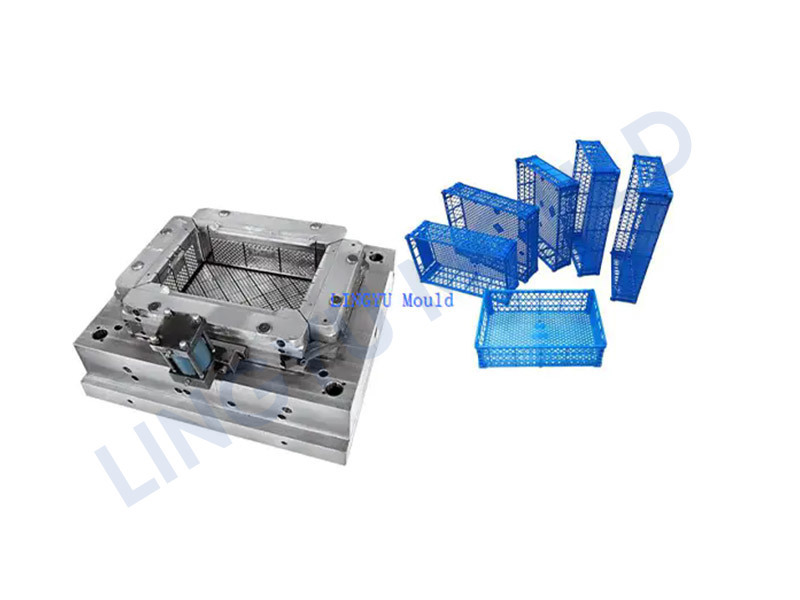

Injection Plastic Basket Mould

Keyword

Classification

Product Details

Description

Injection Plastic Basket Mould uses advanced CAD/CAE/CAM technology and uses UG, CATIA, MOULD FLOW, PRO/E and other software to optimize product design, shorten the cycle of product development and ensure the quality of the mold.

Parameter

|

Plastic rattan Basket Mould |

|||

|

Core/Cavity Steel |

P20 |

||

|

Mould Base |

LKM |

||

|

Mould size |

550*500*650 |

||

|

Cavity |

1 |

||

|

Injection System |

Cold Runner |

||

|

Mould Life |

500,000 shots |

||

|

Plastic material |

PP |

||

|

Design Software |

NX Siemens, PROE, Cimatron, Solidwork,Catia and Auto-CAD |

||

|

Delivery Time |

60days |

||

|

Payment |

By T/T |

||

Maintenance

After the Injection Plastic Basket Mould completes the production task, the residual injection molding should be carefully removed according to different injection molding methods. Copper rods, copper wire and professional mold cleaners can be used to remove residual injection molding and other deposits from the mold and then air dried.

Disable the cleaning of hard objects such as wire and steel bars to avoid scratching the surface. If there is rust caused by corrosive injection molding, use a grinder to grind and polish, and spray professional anti-rust oil, then store the Injection Plastic Basket Mould in a dry, cool, dust-free place.

recommend products

Welcome your message consultation

*Leave your contact information to get a free product quote