Rear fender mould

100L Plastic Dustbin Mould has a high-precision mold clamping, accessories are DME standard

Keyword

fender mould

Classification

Product Details

Description

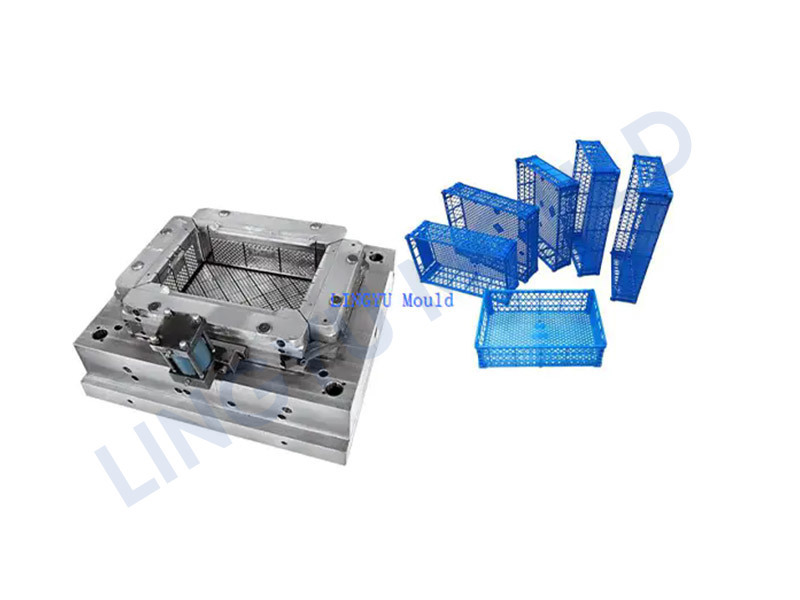

100L Plastic Dustbin Mould has a high-precision mold clamping, accessories are DME standard, inserts and guides to prevent deformation and misalignment. Therefore, a reasonable guiding design can improve the wear resistance, and the reasonable insert material can improve the life of the 100L Plastic Dustbin Mould in a high efficiency process.

Parameter

|

Mould size |

650*650*850 |

||

|

Cavity |

1 |

||

|

Injection System |

Hot Runner |

||

|

Mould Life |

500,000 shots |

||

|

Plastic material |

HDPE |

||

|

Design Software |

NX Siemens, PROE, Cimatron, Solidwork,Catia and Auto-CAD |

||

|

Delivery Time |

65 days |

||

|

Payment |

By T/T |

||

Advantages

The 100L Plastic Dustbin Mould's ejection method is designed to automatically eject the mechanical system to maximize draft angle. In this way, when the mold is opened, the ejection is smoother and more efficient to achieve automatic demolding. The ejection action at the time of mold opening determines the efficiency and thus the cost. The bronze is inlaid on the necessary part of the mold. The characteristics of the bronze help the mold to cool quickly and quickly, which helps to increase the efficiency of the mold by more than 2 times.

recommend products

Welcome your message consultation

*Leave your contact information to get a free product quote