Plastic Injection Mould For Stool

Keyword

Classification

Product Details

Description

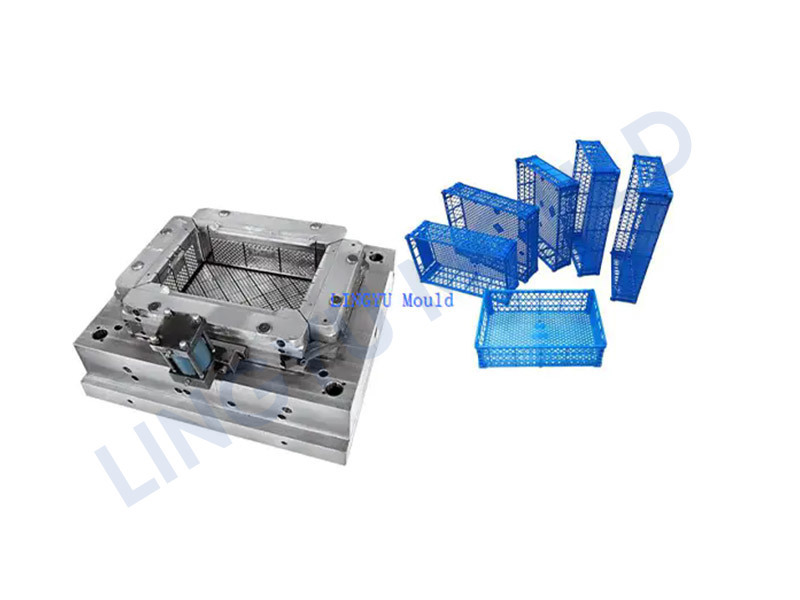

Plastic Injection Mould for Stool is a tool for producing plastic stools. It consists of several sets of parts with a molded cavity. During injection molding, the mold is clamped on the injection molding machine, and the molten plastic is injected into the molding cavity and cooled and shaped in the cavity. The upper and lower dies are then separated, the article is ejected from the mold cavity out of the mold via the ejector system, and the mold is then closed for the next injection. The entire injection molding process is cyclic.

Parameter

|

Plastic arm Chair Mould |

|||

|

Core/Cavity Steel |

P20 |

||

|

Mould Base |

LKM Standard mould base |

||

|

Mould size |

1400*1000*1200 |

|

|

|

Cavity |

1 |

||

|

Injection System |

HOT Runner |

||

|

Mould Life |

500,000 shots |

||

|

Plastic material |

PE |

||

|

Design Software |

NX Siemens, PROE, Cimatron, Solidwork,Catia and Auto-CAD |

||

|

Delivery Time |

65days |

||

|

Payment |

By T/T |

||

Maintenance during mold loading

Before the mold is installed, the upper and lower surfaces of the Plastic Injection Mould for Stool should be cleaned to ensure that the mold mounting surface and the press table are not crushed and the parallelism of the upper and lower mounting surfaces of the mold during production. After the Plastic Injection Mould for Stool is installed, the mold is opened and the parts of the mold are cleaned, especially the guiding mechanism. For the surface part mold, the profile should be cleaned to ensure the quality of the part. Lubricate the sliding parts of the mold and apply grease.

recommend products

Welcome your message consultation

*Leave your contact information to get a free product quote