Plastic Paint Bucket Mould

Keyword

Classification

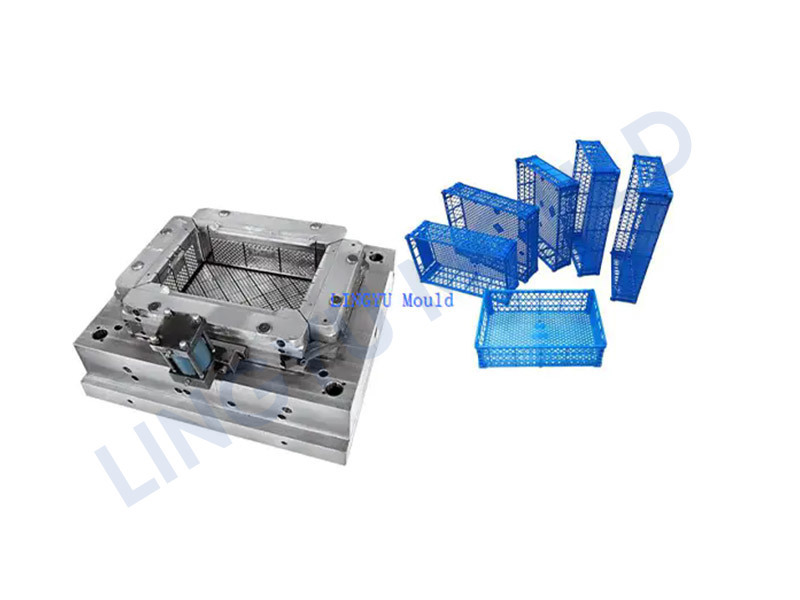

Product Details

Description

The refinement of the Plastic Paint Bucket Mould process makes the processing equipment more complex and efficient. High-speed milling has many advantages such as high-hardness steel that can be processed, smooth machining, small cutting force, and small temperature rise and deformation of the workpiece, which makes mold companies pay more and more attention to high-speed machining.

Parameter

|

Plastic Paint Bucket Mould |

|||

|

Core/Cavity Steel |

H13 |

||

|

Mould Base |

LKM |

||

|

Mould size |

550*550*700 |

||

|

Cavity |

1 |

||

|

Injection System |

Cold Runner |

||

|

Mould Life |

500,000 shots |

||

|

Plastic material |

PE |

||

|

Design Software |

NX Siemens, PROE, Cimatron, Solidwork,Catia and Auto-CAD |

||

|

Delivery Time |

60days |

||

|

Payment |

By T/T |

||

Advantages

The plastic steel material processed by Plastic Paint Bucket Mould has high hardness and requires mold processing equipment with thermal stability and high reliability.

Good materials have better corrosion resistance, toughness, thermal conductivity and hardness, making polishing easier, saving production cycles, extending mold life, reducing maintenance and repair time, reducing the risk of cracking and increasing production efficiency.

recommend products

Welcome your message consultation

*Leave your contact information to get a free product quote