Plastic Car Door Panel Mold

The injection molding requirements of Plastic Car Door

Keyword

Panel Mold

Classification

Product Details

Description

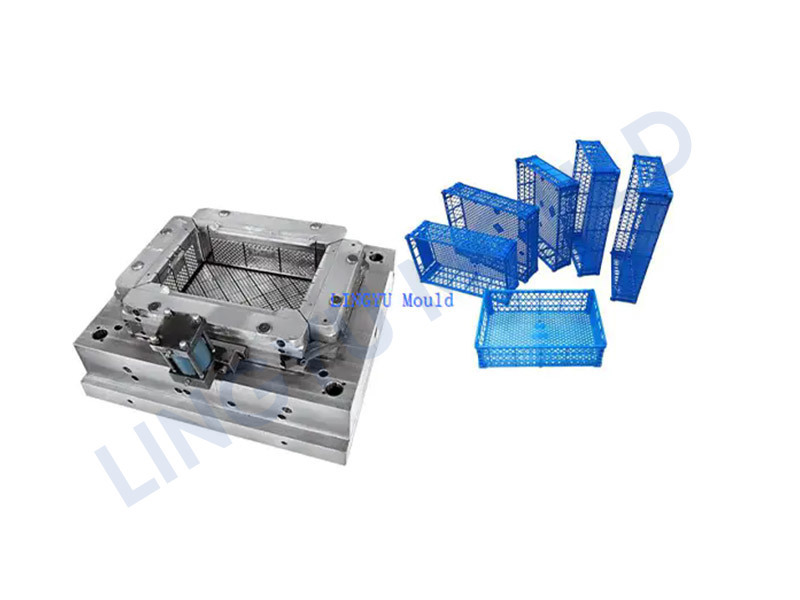

The injection molding requirements of Plastic Car Door Panel Mold products are very strict, and the products are not allowed to have defects such as frontal, shrinking, water-graining, scratching, and lack of glue. Because of the structural reasons of the car door panel mold, generally it will have more than three glue inlets, and the phenomenon of water trapping is easy to occur in the position where the two glues are welded. Make some venting inserts at the relevant parts, and repairing the gap between these inserts can directly affect the effect of the exhaust. Due to the large size of the door panel of the automobile door, it is necessary to gradually control all the links in the production and assembly to ensure the quality of the mold.

Parameter

|

Plastic Car Door Panel Mold |

|

|

Core/Cavity Steel |

P20 |

|

Mould Base |

LKM |

|

Mould SpareParts |

SKD 61 |

|

Cavity |

Single |

|

Injection System |

Hot Runner |

|

Runner |

Yudo/DME/HUSkY |

|

Mould Life |

1,000,000 shots |

|

Plastic material |

PP |

|

Design Software |

NX Siemens, PROE, Cimatron, Solidwork,Catia and Auto-CAD |

|

Delivery Time |

90 days |

|

Payment |

By T/T |

Precautions

It is easy to leak the front of the car's door. Because the Plastic Car Door Panel Mold has a large number of sloping tops and straight tops, some minor errors in the repair and installation may lead to the front. The door panel mold of the automobile has a large area to be inserted and penetrated. In these positions, the error in the repairing process may also cause the mold to leak.

recommend products

Welcome your message consultation

*Leave your contact information to get a free product quote