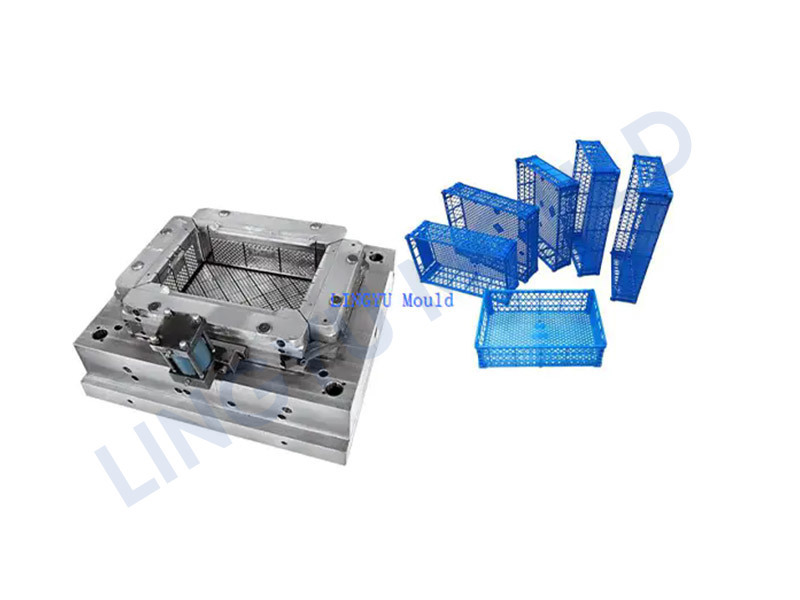

Plastic Injection Tray Mould

Keyword

Classification

Product Details

Description

Plastic Injection Tray Mould adopts the international advanced level special flow channel design. The mold cooling adopts circulating water to effectively improve the efficiency of product ejection. The mold fasteners are made of 12.9 high-strength bolts, and the sliders are made of special tie rods. The production efficiency of the products can be increased by more than 50%. Plastic Injection Tray Mould guarantees that the product will not suffer from visual effects such as warpage, flashing, shrinkage, and injection hole marks.

Parameter

|

Plastic rectangle Tray Mould |

|||

|

Core/Cavity Steel |

H13 |

||

|

Mould Base |

LKM |

||

|

Mould size |

650*500*500 |

||

|

Cavity |

1 |

||

|

Injection System |

Cold Runner |

||

|

Mould Life |

500,000 shots |

||

|

Plastic material |

PP |

||

|

Design Software |

NX Siemens, PROE, Cimatron, Solidwork,Catia and Auto-CAD |

||

|

Delivery Time |

60days |

||

|

Payment |

By T/T |

||

Process

It is nitrided to make the Plastic Injection Tray Mould deform less, increase the hardness and wear resistance of the mold surface, effectively extend the life of the mold, and make the mold more durable.

It uses an electroplating process to increase the brightness and corrosion resistance of the molding surface, and is very suitable for transparent parts that require polishing.

The chrome treatment makes the mold corrosion-resistant, making the mold look brighter and longer lasting.

recommend products

Welcome your message consultation

*Leave your contact information to get a free product quote