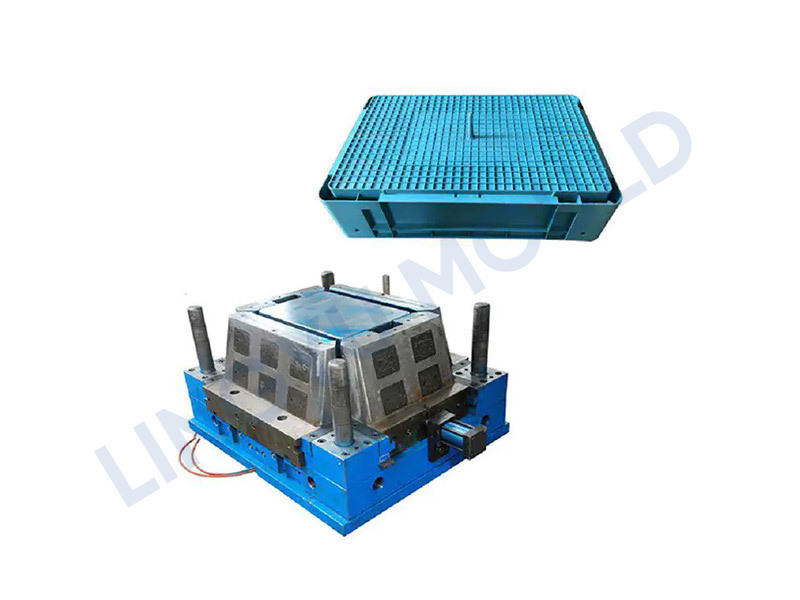

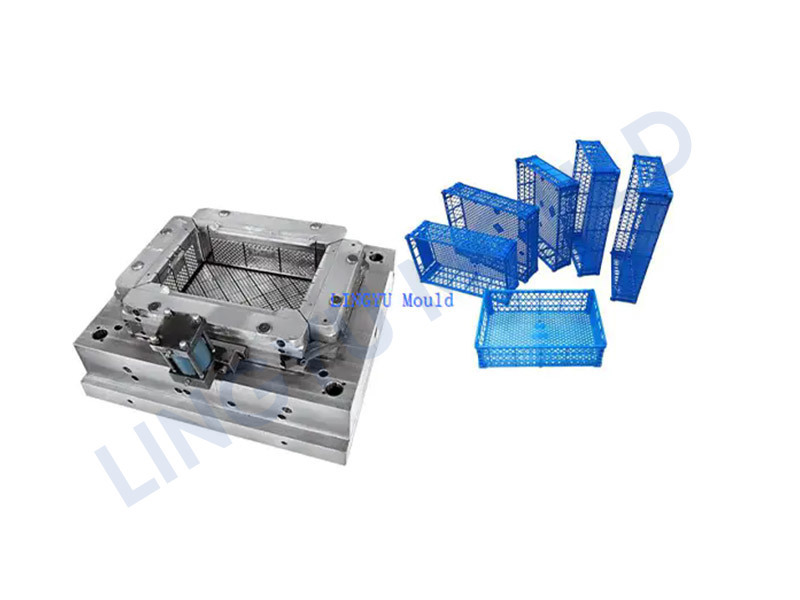

Plastic Injection Turn Over Storage Mould

Keyword

Classification

Product Details

Description

Plastic Injection Turn Over Storage Mould uses Moldflow flow analysis software to optimize the casting system. It adopts two-point pouring and point gate form to improve the flow filling performance of plastic and ensure the quality of plastic parts. Plastic Injection Turn Over Storage Mould uses a hot runner casting system to change the mold structure from a three-plate structure to a two-plate structure, and the mold structure is further optimized.

Parameter

|

Plastic Injection Turn Over Storage Mould Factory |

|||

|

Core/Cavity Steel |

P20 |

||

|

Mould Base |

LKM |

||

|

Mould size |

850*650*500 |

||

|

Cavity |

1 |

||

|

Injection System |

Cold Runner |

||

|

Mould Life |

500,000 shots |

||

|

Plastic material |

HDPE |

||

|

Design Software |

NX Siemens, PROE, Cimatron, Solidwork,Catia and Auto-CAD |

||

|

Delivery Time |

40 days |

||

|

Payment |

By T/T |

||

Precautions

(1) For the formwork and core and cavity parts of the Plastic Injection Turn Over Storage Mould, the appropriate material and material hardness should be selected, as well as the appropriate mold standard parts. This will avoid problems during use.

(2) For the friction in the tote mold and its guiding part, it is necessary to pay attention to its processing. Moreover, no problems can occur during the processing. In addition, manual operation is not possible, so as not to affect the processing effect and quality, which in turn affects the quality of the totes.

recommend products

Welcome your message consultation

*Leave your contact information to get a free product quote