Car Rear Inner Fender Mold

Injection molding is the most commonly used molding and processing method

Keyword

Fender Mold

Classification

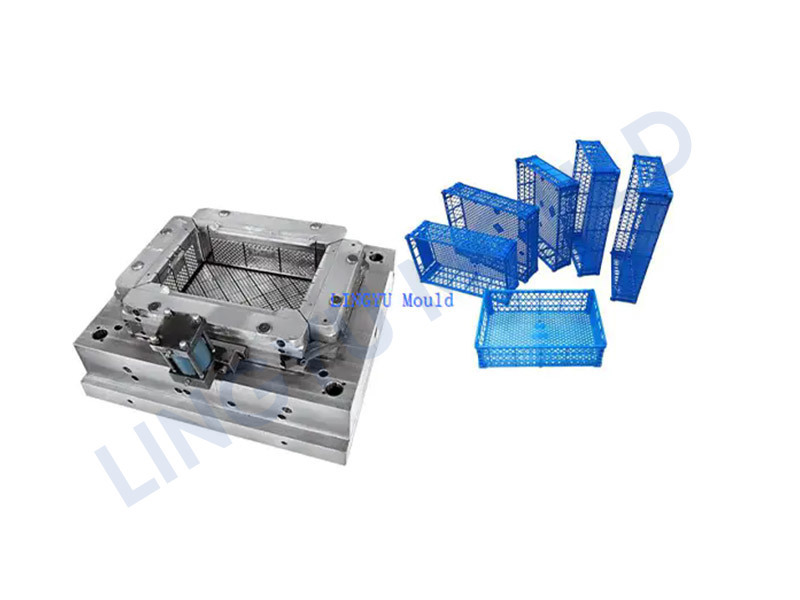

Product Details

Description

Injection molding is the most commonly used molding and processing method for plastic products. Car Rear Inner Fender injection molding is the process of adding raw materials of granular or powdered plastic into the barrel of injection molding machine through a hopper. The plastic material is plasticized into a good flow under the action of electric heating and mechanical shearing force and shear heat provided by it. The melt is melted. Then, under the parallel push of the plunger or the screw, the plastic melt passes through the main flow through the cylinder, and the runner and gate are sprayed at a very fast speed into the low temperature Car Rear Inner Fender Mold. It is then cooled and solidified to form a plastic product that conforms to the shape of the cavity surface. The product generally has the characteristics of high precision, good quality and strong consistency.

Parameter

|

Car Rear Inner Fender Mold |

|||

|

Core/Cavity Steel |

P20 |

||

|

Mould Base |

LKM |

||

|

Mould size |

850*650*650 |

||

|

Cavity |

1 |

||

|

Injection System |

hot Runner |

||

|

Mould Life |

500,000 shots |

||

|

Plastic material |

PE |

||

|

Design Software |

NX Siemens, PROE, Cimatron, Solidwork,Catia and Auto-CAD |

||

|

Delivery Time |

65 days |

||

|

Payment |

By T/T |

||

Advantages

Car Rear Inner Fender Mold can quickly mold most of the products with complex structures, high dimensional accuracy and some metal inserts.

The surface of the product can be almost as rough as the surface of the mold cavity, or the same texture.

The molding cycle consumes a short time and can produce a plurality of products through one production cycle, thereby achieving high production efficiency.

recommend products

Welcome your message consultation

*Leave your contact information to get a free product quote